Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§229.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes [ ] No [ ]

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405) is not contained herein, and will not be contained, to the best of registrant’s knowledge in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. [X ]

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, non-accelerated filer, or a smaller reporting company. See definitions of “large accelerated filer”, “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

| Large accelerated filer [ ] | Accelerated filer [ ] |

| Non-accelerated filer [ ] (do not check if a smaller reporting company) | Smaller Reporting Company [X] |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes [ ] No [X]

As of March 31, 2009, the aggregate market value of the voting and non-voting stock held by non-affiliates of the registrant was approximately $28,722,000, based upon the closing sales price reported by the NASDAQ Global Market on that date.

As of November 18, 2009, the registrant had outstanding 8,964,244 shares of Common Stock, $0.01 par value.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Definitive Proxy Statement related to the registrants 2009 Annual Meeting of Shareholders, which Proxy Statement will be filed under the Securities Exchange Act of 1934, as amended, within 120 days of the end of the registrant’s fiscal year ended September 30, 2009, are incorporated by reference into Items 10-14 of Part III of this Form 10-K.

AMTECH SYSTEMS, INC. AND

SUBSIDIARIES

Table of Contents

| Part I | ||

| Item 1. | Business | 3 |

| Item 1A. | Risk Factors | 15 |

| Item 1B. | Unresolved Staff Comments | 23 |

| Item 2. | Properties | 24 |

| Item 3. | Legal Proceedings | 24 |

| Item 4. | Submission of Matters to a Vote of Security Holders | 24 |

| Part II | ||

| Item 5. | Market for Registrant’s Common Equity, Related Stockholder Matters | |

| and Issuer Purchases of Equity Securities | 25 | |

| Item 6. | Selected Financial Data | 27 |

| Item 7. | Management’s Discussion and Analysis of Financial Condition and | |

| Results of Operations | 27 | |

| Item 7A. | Quantitative and Qualitative Disclosures about Market Risk | 41 |

| Item 8. | Financial Statements and Supplementary Data | 42 |

| Item 9. | Changes in and Disagreements with Accountants on Accounting and | |

| Financial Disclosure | 70 | |

| Item 9A. | Controls and Procedures | 70 |

| Item 9B. | Other Information | 70 |

| Part III | ||

| Item 10. | Directors, Executive Officers and Corporate Governance | 71 |

| Item 11. | Executive Compensation | 71 |

| Item 12. | Security Ownership of Certain Beneficial Owners and Management and | |

| Related Stockholder Matters | 71 | |

| Item 13. | Certain Relationships and Related Transactions, and Director | |

| Independence | 71 | |

| Item 14. | Principal Accountant Fees and Services | 71 |

| Part IV | ||

| Item 15. | Exhibits and Financial Statement Schedules | 71 |

| Signatures | 72 | |

2

FORWARD-LOOKING STATEMENTS

Certain information contained or incorporated by reference in this Annual Report on Form 10-K is forward-looking in nature. All statements included or incorporated by reference in this Annual Report on Form 10-K, or made by management of Amtech Systems, Inc. and its subsidiaries (“the Company” or “Amtech”), other than statements of historical fact, are hereby identified as “forward-looking statements” (as such term is defined in Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended). Examples of forward-looking statements include statements regarding Amtech’s future financial results, operating results, business strategies, projected costs, products under development, competitive positions and plans and objectives of the Company and its management for future operations. In some cases, forward-looking statements can be identified by terminology such as “may,” “will,” “should,” “would,” “expects,” “plans,” “anticipates,” “intends,” “believes,” “estimates,” “predicts,” “potential,” “continue,” or the negative of these terms or other comparable terminology. Any expectations based on these forward-looking statements are subject to risks and uncertainties and other important factors, including those discussed in the section entitled “ITEM 1A. RISK FACTORS.” These and many other factors could affect Amtech’s future operating results and financial condition, and could cause actual results to differ materially from expectations based on forward-looking statements made in this document or elsewhere by Amtech or on its behalf.

All references to “we,” “our,” “us,” or “Amtech” refer to Amtech Systems, Inc. and its subsidiaries.

PART I

ITEM 1. BUSINESS

Amtech was incorporated in Arizona in October 1981, under the name Quartz Engineering & Materials, Inc. We changed to our present name in 1987. We conduct operations through four wholly-owned subsidiaries: Tempress Systems, Inc., a Texas corporation with all of its operations in The Netherlands, acquired in 1994, also referred to herein as Tempress Systems or Tempress®; P.R. Hoffman Machine Products, Inc. (PR Hoffman), an Arizona corporation based in Carlisle, Pennsylvania, acquired in July 1997; Bruce Technologies, Inc. (Bruce Technologies®), a Massachusetts corporation based in Billerica, Massachusetts, acquired in July 2004, or Bruce Technologies; and R2D Automation SAS (R2D), a French corporation located near Montpellier, France, acquired in October 2007. See Exhibit 21.1 Subsidiaries for a complete list of our subsidiaries.

We are a leading supplier of horizontal diffusion furnace systems used for solar (photovoltaic) cell and semiconductor manufacturing, and are recognized in the markets we serve for our technology and our brands. We operate in two business segments: (i) solar and semiconductor equipment and (ii) polishing supplies. Our solar and semiconductor equipment is sold under the well-known and respected brand names of Tempress Systems and Bruce Technologies, which have customers in both the solar industry and the semiconductor industry. Within the solar industry, we provide diffusion and automation equipment to solar cell manufacturers. Within the semiconductor industry, we provide equipment to manufacturers of analog, power, automotive and microcontroller chips with geometries greater than 0.3 micron, a strategy we believe minimizes direct competition with significantly larger suppliers of semiconductor equipment. Under the PR Hoffman brand, we believe we are also a leading supplier of insert carriers to manufacturers of silicon wafers, and we provide lapping and polishing consumable products as well as equipment used in various industries.

We have been providing manufacturing solutions to the semiconductor industry for over 30 years and are leveraging our semiconductor technology and industry presence in an effort to capitalize on growth opportunities in the solar industry. Our customers use our furnaces to manufacture solar cells, semiconductors, silicon wafers and microelectromechanical systems (MEMS), which are used in end markets such as solar power, telecommunications, consumer electronics, computers, automotive and hand-held devices. To complement our research and development efforts, we also sell our furnaces to research institutes and universities.

For fiscal 2009, we recognized net revenue of $53.0 million, which included $34.8 million of solar revenue or approximately 66% of our total revenue. These results compare to $80.3 million of net revenue for fiscal 2008, which included $50.1 million of solar revenue or approximately 62% of our total revenue. Our order backlog as of September 30, 2009 and 2008 was $32.4 million and $46.7 million, respectively, a 31% decrease. Our backlog as of September 30, 2009 included approximately $27.9 million of orders from our solar industry customers compared to $36.7 million of orders from our solar industry customers as of September 30, 2008. Because our orders are typically subject to cancellation or delay by the customer, our backlog at any particular point in time is not necessarily representative of actual sales in subsequent periods, nor is backlog any assurance that we will realize revenue or profit from completing these orders.

3

Orders from the solar industry totaled $21.8 million during fiscal 2009, compared to $73.3 million and $20.5 million in fiscal 2008 and 2007, respectively.

For information regarding net revenue, operating income and identifiable assets attributable to each of our two business segments, see Note 9 of the Notes to Consolidated Financial Statements included herein and “ITEM 7, MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS” of this Annual Report. For information on the products of each segment, see “Solar and Semiconductor Equipment Segment Products” and “Polishing Supplies Segment Products” within this “ITEM 1. BUSINESS” section. For information regarding the impact of the worldwide economic downturn and other risks to our business, see “ITEM 1A. RISK FACTORS.”

COMPETITIVE STRENGTHS

We believe that we are a leader in the markets we serve as a result of the following competitive strengths:

Leading Market Share and Recognized Brand Names. The Tempress, Bruce Technologies and PR Hoffman brands have long been recognized in our industry and identified with high-quality products, innovative solutions and dependable service. We believe that our brand recognition and experience will continue to allow us to capitalize on current and future market opportunities in the solar industry.

We have been providing horizontal diffusion furnaces and polishing supplies and equipment to our customers for over 30 years. We have sold and installed over 900 horizontal furnaces worldwide and benefit from what we believe to be the largest installed customer base in the semiconductor industry, which we believe offers an opportunity for replacement and expansion demand. We also have a retrofit, parts and service business, which typically generates higher margins than our equipment business.

Experienced Management Team. We are led by a highly experienced management team. Our chief executive officer (CEO) has over 36 years of industry experience, including 28 years with our company. Our four general managers have an average of nearly 21 years of solar and semiconductor industry experience and an average of 20 years with our company (including our predecessor companies).

Established, Diversified Customer Base. We have long-standing relationships with many of our top customers, which we believe remain strong. We maintain a broad base of customers, including leading solar cell manufacturing companies, as well as semiconductor and wafer manufacturing companies. During fiscal 2009, our largest customer accounted for approximately 16% of our net revenue and our top 10 customers collectively represented approximately 62% of our net revenue. In fiscal 2008, our largest customer accounted for approximately 20% of our net revenue, and our top 10 customers collectively represented approximately 62% of our net revenue. In fiscal 2007, our largest customer accounted for approximately 13% of our net revenue, and our top 10 customers collectively represented approximately 52% of our net revenue. E-Ton Solar Tech accounted for 16%, 4% and 13% of our net revenue in fiscal 2009, 2008 and 2007, respectively. At the end of fiscal 2009 and 2008, 31% and 40% of our total backlog consisted of orders and deferred revenue from E-Ton Solar Tech, respectively. The customer-supplier relationship is our sole relationship with E-Ton Solar Tech.

Proven Acquisition Track Record. Over the last fifteen years we have developed an acquisition program that has resulted in the acquisition of four significant businesses. In October 2007, we acquired R2D, a solar and semiconductor automation company located near Montpellier, France. We believe the acquisition of the technology and business of R2D enhances our growth strategy by allowing us to increase our sales by offering an integrated system under the Tempress brand to the solar industry. In July 2004, we acquired the Bruce Technologies line of semiconductor horizontal furnace operations, product lines and other assets from Hitachi-Kokusai, a wholly-owned subsidiary of Hitachi, Japan and its affiliate, Kokusai Electric Europe, GmbH. Bruce Technologies has a large installed base, including several large semiconductor manufacturers. In July 1997, we acquired substantially all of the assets of PR Hoffman. This acquisition enabled us to offer new consumable products, including lapping and polishing carriers, polishing templates, lapping and polishing machines and related consumable and spare parts to our existing customer base as well as to target new customers. In 1994, we acquired certain assets of Tempress and hired Tempress’s engineers to develop our first models of the Tempress horizontal diffusion furnaces for production in The Netherlands.

Technical Expertise. We have highly trained and experienced mechanical, chemical, environmental, electronic, hardware and software engineers and support personnel. Our engineering group possesses core competencies in product applications and support systems, automation, sophisticated controls, chemical vapor deposition, diffusion and pyrogenic processes, robotics, vacuum systems, ultra clean applications and software driven control packages. We believe this expertise enables us to design, develop and deliver high-quality, technically-advanced integrated product solutions for solar cell and semiconductor manufacturing customers.

4

Leading Technology Solutions and New Product Development. We pursue a partnering-based approach, in which our engineering and development teams work closely with our customers to ensure our products are tailored to meet our customers’ specific requirements. We believe this approach enables us to more closely align ourselves with our customers and provide them with superior systems. We believe our line of horizontal diffusion furnaces, which allow high wafer-per-hour throughput, is more technologically advanced and reliable than most of our competitors’ equipment. In addition, the processing and temperature control systems within the furnace provide diverse and proven process capabilities, which enable the application of high-quality films onto silicon wafers. We believe our recently acquired R2D solar automation technology will provide efficiencies in the manufacturing process that will allow our customers to be more competitive in their respective markets. Additionally, our license agreements in the areas of PSG dry-etch and PECVD anti-reflective coatings allows us to expand our solar product offering. We developed a small batch vertical furnace jointly with a major European semiconductor customer and are currently developing multiple thin film processes for use with this furnace. We retain full ownership of this technology. In 2007, we also began selling precision thickness wafer carriers. This is an internally developed product that we expect will increase our sales to the wafer carrier market.

GROWTH STRATEGY

Capitalizing on Growth Opportunities in the Solar Industry. We have had success in penetrating the solar market. Our orders for solar diffusion and automation systems in fiscal 2009 totaled $21.8 million despite the severe worldwide economic downturn. Our fiscal 2008 solar orders totaled $73.3 million compared to $20.5 million in fiscal 2007. We believe that our success with solar cell manufacturers is due to our focused process and product development and marketing efforts, as well as the growing overall demand from the solar industry. We believe that long-term growth in the solar industry will be driven by rising energy demand, the increasing scarcity of traditional energy resources coupled with rising prices, the growing adoption of government incentives for solar energy due to increasing environmental awareness and concern about energy independence, the gradually decreasing cost of solar energy and the changing consumer preferences toward renewable energy sources.

Accelerating New Product and Technology Development. We are focused on acquiring, developing and licensing new products across our business in response to customer needs in various markets.

Leveraging our Installed Base. We intend to continue leveraging our relationships with our customers to maximize parts, system, service and retrofit revenue from the large installed base of Bruce Technologies and Tempress brand horizontal diffusion furnaces. We intend to accomplish this by meeting these customers’ needs for replacement systems and additional capacity, including equipment and services in connection with any of our customers’ relocation to, or expansion efforts in, Asia.

Pursuing Strategic Acquisitions that Complement our Strong Platform. Over the last twelve years, we have developed an acquisition program and have completed the acquisition of three significant businesses. Based on a disciplined acquisition strategy, we continue to evaluate potential technology, product and business acquisitions or joint ventures that are intended to increase our existing market share in the solar industry and expand the number of front-end semiconductor processes addressed by our products. In evaluating these opportunities, our objectives include: enhancing our earnings and cash flows, adding complementary product offerings, expanding our geographic footprint, improving our production efficiency and growing our customer base.

SOLAR AND SEMICONDUCTOR INDUSTRIES

We provide products and services primarily to two industries: the solar industry and the semiconductor industry.

Solar Industry. Solar power has emerged as one of the most rapidly growing renewable energy sources. To date, various technologies have been developed to harness solar energy. The most significant technology is the use of interconnected photovoltaic, or PV, cells to generate electricity directly from sunlight. Most PV cells are constructed using specially processed silicon, which, when exposed to sunlight, generates direct current electricity. Solar energy has many advantages over other existing renewable energy sources and traditional non-renewable energy sources in the areas of environmental impact, delivery risk, distributed nature of generation and matching of peak generation with demand.

Semiconductor Industry. Semiconductors control and amplify electrical signals and are used in a broad range of electronic products, including: consumer electronic products, computers, wireless telecommunication devices, communications equipment, automotive electronic products, major home appliances, industrial automation and control systems, robotics, aircraft, space vehicles, automatic controls and high-speed switches for broadband fiber optic telecommunication networks. Semiconductors, or semiconductor “chips” and optical components are manufactured primarily on a silicon wafer and are part of the circuitry or electronic components of many of the products listed above.

5

The semiconductor industry has experienced significant growth since the early 1990s. This growth has been primarily attributable to an increase in demand for personal computers, the growth of the Internet, the expansion of the telecommunications industry, especially wireless communications, and the emergence of new applications in consumer electronics. Further fueling this growth is the rapidly expanding end-user demand for smaller, less-expensive and better-performing electronic products as well as for traditional products with more “intelligence.” This growing demand has led to an increased number of semiconductor devices in electronic and other consumer products, including automobiles.

Although the semiconductor market has experienced significant growth over the past fifteen years, it remains cyclical by nature. The market is characterized by short-term periods of under or over supply for most semiconductors, including microprocessors, memory, power management chips and other logic devices. When demand decreases, semiconductor manufacturers typically slow their purchasing of capital equipment. Conversely, when demand increases, so does capital spending.

Industry Manufacturing Processes

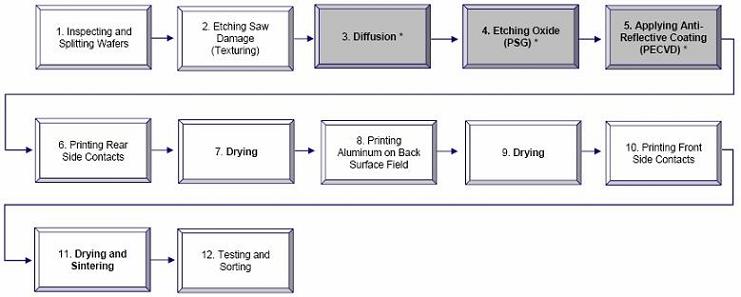

Solar Cell Manufacturing Process Flow Chart

| (*) | Manufacturing process step which involves the use of our products. |

6

A part of our growth strategy involves evaluating opportunities to increase the number of process steps we serve in both the solar cell and semiconductor manufacturing processes by acquiring additional product lines. The solar industry uses many similar process steps used in semiconductor manufacturing in the high-volume production of solar cells including:

| (1) | inspecting for resistivity and mechanical integrity and splitting wafers; | ||

| (2) | etching away saw damage with sodium hydroxide and rinsing the wafer with water and concentrated sulphuric acid; | ||

| (3) | diffusing phosphorous oxychloride on the wafer; | ||

| (4) | etching the wafer with hydrofluoric acid to remove the undiffused, phosphorus-silica-glass layer; | ||

| (5) | coating an antireflective layer through a chemical vapor deposition (CVD) or plasma enhanced CVD process; | ||

| (6) | printing rear side contacts; | ||

| (7) | drying to prevent condensation in the wafer area; | ||

| (8) | printing aluminum and silver paste on the back surface field to prevent recombination of generated electrons and holes; | ||

| (9) | drying; | ||

| (10) | printing front side contacts; | ||

| (11) | drying and then sintering the contact to form electrical conductive contacts; and | ||

| (12) | testing and sorting the solar cells into electrical efficiency categories. | ||

Most solar cell manufacturers sell their products to manufacturers of solar modules or solar panels. Others are vertically integrated and use their cells in the production of solar modules and panels. Solar cells are the critical component of solar modules and solar panels, which are sold to the end user and used in residential homes, industrial applications, remote pumping, lighting and heating uses and central power stations.

7

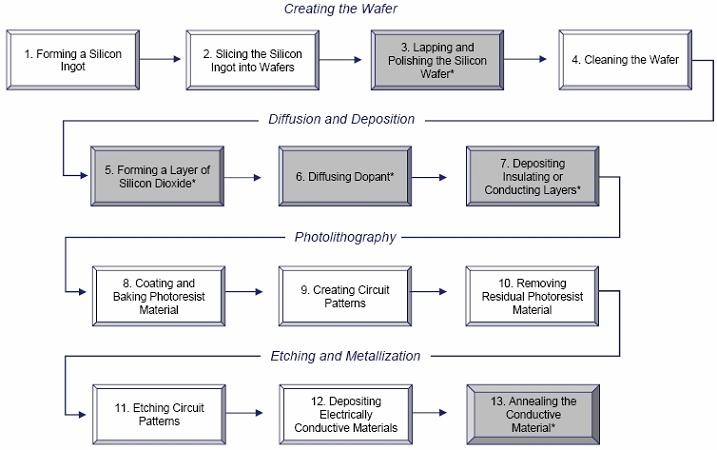

Semiconductor Front End Manufacturing Process Flow Chart

| * |

Manufacturing process steps which are performed using our products. |

Most semiconductor chips are built on a base of silicon, called a wafer, and include multiple layers of circuitry that connect a variety of circuit components, such as transistors, capacitors and other components. To build a chip, the transistors, capacitors and other circuit components are first created on the surface of the wafer by performing a series of processes to deposit and remove selected film layers, including insulators. Similar processes are then used to build the layers of wiring structures on the wafer. These are all referred to as “front-end” processes. A simplified sequence of front-end processes for fabricating typical chips involves:

8

| (1) | forming an ingot by pulling molten silicon; | ||

| (2) | slicing the silicon ingot into wafers of uniform thickness with a wire saw; | ||

| (3) | lapping and polishing the silicon wafer to a mirror-like finish; | ||

| (4) | cleaning the wafer; | ||

| (5) | forming a thin film-layer of silicon dioxide on the wafer in a diffusion furnace where oxygen, hydrogen or a combination of the two is introduced to cause a chemical reaction (oxidation) with the silicon wafer’s surface; | ||

| (6) | diffusing impurities (doping) in order to change the wafer’s electrical properties. | ||

| (7) | depositing insulating or conducting layers on the wafer surface, which sometimes is accomplished in a diffusion furnace via a chemical reaction called chemical vapor deposition; | ||

| (8) | coating and baking a photosensitive material, called photoresist, on the wafer; | ||

| (9) | creating circuit patterns by exposing the wafer to light directed through a mask with circuit patterns; | ||

| (10) | removing the soluble portion of the photoresist by placing the wafer in a chemical solution, leaving only the desired pattern; | ||

| (11) | etching away the exposed areas to create a dimensional pattern on the wafer surface; | ||

| (12) | creating electrically charged conductive regions by driving ions into the exposed areas of the patterned wafer; and | ||

| (13) | annealing the wafer through a high temperature process to relieve stress and drive the implanted ions deeper into the wafer. | ||

The silicon wafer may be cycled ten to twenty-five times through these wafer-processing steps, starting each time at step (5) or (7) to form a number of chips on the wafer. The front-end process steps are followed by a number of back-end steps in which the wafers are sliced into individual chips that are then packaged to add connectors that are compatible with the end product in which the chip will be used.

Depending on the device, our polishing supplies segment’s products may be used in lapping and polishing (step 3) and our solar and semiconductor equipment segment’s products may be used in forming silicon dioxide films (step 5), doping (step 6), depositing insulating and conducting layers (step 7) and the annealing processes (step 13).

SOLAR AND SEMICONDUCTOR EQUIPMENT SEGMENT PRODUCTS

Our furnace and automation equipment is manufactured in our facilities in The Netherlands, France, and Massachusetts. The following paragraphs describe the products that comprise our solar and semiconductor equipment segment:

Horizontal Diffusion Furnaces. Through our subsidiaries, Tempress and Bruce Technologies, we produce and sell horizontal diffusion furnaces. Our horizontal furnaces currently address several steps in the semiconductor manufacturing process, including diffusion (step 5 in the semiconductor manufacturing process previously described), phosphorus tetrachloride doping, or POCl3 (step 6), low-pressure chemical vapor deposition, or LPCVD, (step 7), and annealing (step 13). Our horizontal furnaces also currently address diffusion and applying antireflective coating in the solar cell manufacturing process (steps 3 and 5).

Our horizontal furnaces generally consist of three large modules: the load station where the loading of the wafers occurs; the furnace section, which is comprised of one to four reactor chambers; and the gas distribution cabinet where the flow of gases into the reactor chambers is controlled, and often customized to meet the requirements of a customer’s particular processes. The horizontal furnaces utilize existing industry technology and are sold primarily to customers who do not require the advanced automation of, or cannot justify the higher expense of, vertical furnaces for some or all of their diffusion processes. Our models are capable of processing all currently existing wafer sizes.

9

PSG Dry Etch. The PSG dry etch process step in the manufacturing of solar cells removes phosphorus silicate glass (PSG) that naturally occurs during the diffusion process. We will use our license of this unique PSG technology, which will be manufactured by PST, to expand our presence in the growing solar market.

Plasma-Enhanced Chemical Vapor Deposition (PECVD). Our new solar PECVD product applies an anti-reflective coating to solar wafers; a coating critical to the efficiency of solar cells. This solar product adds another solar cell processing step to Amtech's offerings.

Automation Products – Solar. Our automation technology products are used in several of the semiconductor manufacturing steps and the diffusion processing step in solar cell manufacturing. Our automation equipment includes mass wafer transfer systems, sorters, long-boat transfer systems, load station elevators, buffers and conveyers. We use a vacuum technology for our solar wafer transfer systems designed to ensure high throughput.

Automation Products – Semiconductor. Use of our automation products reduces human handling and, therefore, reduces exposure of wafers to particle sources during the loading and unloading of the process tubes and protects operators from heat and chemical fumes. The top reactor chamber of a horizontal furnace can be as much as eight feet from the floor on which the operator stands when manually loading wafer boats. Typical boats of 150mm to 300mm wafers weigh three to six pounds. Given these two factors, automating the wafer loading and unloading of a diffusion furnace improves employee safety and ergonomics in silicon wafer, solar cell and semiconductor manufacturing facilities.

S-300. Our patented S-300 model provides a very efficient method of automatically transporting a full batch of up to 300 wafers to the designated tube level and automatically placing them directly onto the cantilever loader of a diffusion furnace at one time. This product is suitable for the production of nearly all semiconductors manufactured using a horizontal furnace. The S-300 can be used in conjunction with all current wafer sizes and is particularly well suited for manufacturers of 300mm wafers.

Comet. Our Comet and Gemini series of wafer transfer systems include a wide range of throughputs and footprints to meet the needs of our customers who serve the semiconductor industry. Comet Sorter with Optical Character Recognition (OCR) is used in sorting, randomizing or compacting. The Comet Sorter is a cassette to cassette with OCR front and back scribe functions, notch alignment and SECSII communication. Comet ID Reader checks tag carriers then reads each wafer scribe. The Comet ID Reader sends the information to the host with SECSII Gem commands.

Small Batch Vertical Furnace. Our small batch, two-tube vertical furnace was developed internally with the active support from a large semiconductor manufacturer and long-term customer. The specifications for this furnace include a two-tube vertical furnace for wafer sizes of up to 200mm, with each tube having a small flat zone capable of processing 25-50 wafers per run. The market for vertical furnaces is much larger than the total of all the other markets we currently serve. We are initially targeting niche applications, including research and development, while we continue to develop additional processes, since the competition in the large batch vertical furnace market is intense and our competitors are much larger and have substantially greater financial resources, processing knowledge and advanced technology.

Conveyor Furnace. We produce conveyor furnaces used to manufacture thick films for the electronics industry. Conveyor furnaces provide for precision thermal processing of electronic parts for thick film applications, including annealing, sealing, soldering, silvering, curling, brazing, alloying, glass-metal sealing and component packaging.

POLISHING SUPPLIES SEGMENT PRODUCTS

The products of our polishing supplies segment are used primarily for lapping and polishing raw silicon wafers to a mirror-like finish. Depending on the cycle of the semiconductor industry, approximately two-thirds of this segment’s products are sold to either semiconductor wafer manufacturers or specialty semiconductor fabricators. The products of our polishing supplies segment are also sold to fabricators of optics, quartz, ceramics and metal parts, and to manufacturers of medical equipment components and computer disks. We manufacture the products described below in Pennsylvania and sell them under our PR Hoffman brand name.

10

Wafer Carriers. Carriers are work holders into which silicon wafers or other materials are inserted for the purpose of holding them securely in place during the lapping and polishing processes. We produce carriers for our line of lapping and polishing machines, as well as for those machines sold by our competitors. Substantially all of the carriers we produce are customized for specific applications. Insert carriers, our most significant category of carriers, contain plastic inserts molded onto the inside edge of the work-holes of the carrier, which hold the wafers in place during processing. Although our standard steel carriers are preferred in many applications because of their durability, rigidity and precise dimensions, they are typically not suited for applications involving softer materials or when metal contamination is an issue. Insert carriers, however, are well suited for processing large semiconductor wafers, up to 300mm in diameter, and other fragile materials or where contamination is an issue, because they provide the advantages of steel carriers while reducing the potential for damage to the edges of such sensitive materials. Our insert carriers are used for double-sided lapping or polishing of semiconductor wafers up to 300mm in diameter. We internally developed and began selling precision thickness wafer carriers in 2007.

Semiconductor Polishing Templates. Our polishing templates are used to securely hold silicon wafers in place during single-sided polishing processes. Polishing templates are customized for specific applications and are manufactured to exacting tolerances. We manufacture polishing templates for most brands of tools and various processes. In addition to silicon wafers, these products are used in polishing silicon carbide wafers and sapphire crystals used in LEDs.

Double-Sided Planetary Lapping and Polishing Machines. Double-sided lapping and polishing machines are designed to process thin and fragile materials, such as semiconductor silicon wafers, precision optics, computer disk media and ceramic components for wireless communication devices, to exact tolerances of thickness, flatness, parallelism and surface finish. On average, we believe that we offer our surface processing systems at a lower price than systems offered by our competitors and target the semiconductor, optics, quartz, ceramics, medical, computer disk and metal working markets. During fiscal 2004, we introduced and delivered our first Model 5400 lapping and polishing machine, capable of processing parts up to 19.5 inches in diameter, including 300mm wafers and higher capacities of smaller parts. This machine is our largest and is superior to our previous model, because it uses servo motors rather than hydraulics and is equipped with a Windows touch-screen interface, for better control of speeds and pressure, optional thickness control, and crash protection. We believe our 5400 model is especially well-suited for thin and fragile materials. We also produce and sell a wide assortment of plates, gears, parts and wear items for our own machines and those sold by many of our competitors.

MANUFACTURING, RAW MATERIALS AND SUPPLIES

Our solar and semiconductor equipment manufacturing activities consist primarily of engineering design, procurement and assembly of various commercial and proprietary components into finished diffusion furnace systems in Vaassen, The Netherlands, France, and Billerica, Massachusetts.

Nearly all of our fabricated parts for the solar and semiconductor equipment segment are purchased from local suppliers. Our manufacturing activities in the polishing supplies and equipment segment include laser-cutting and other fabrication steps in producing lapping and polishing consumables, including carriers, templates, gears, wear items and spare parts in Carlisle, Pennsylvania, from raw materials manufactured to our specifications by our suppliers. Many items, such as proprietary components for our solar and semiconductor equipment and lapping plates, are also purchased from suppliers who manufacture these items to our specifications.

All final assembly and tests of our equipment and machines are performed within our manufacturing facilities. Quality control is maintained through inspection of incoming materials and components, in-process inspection during equipment assembly, testing of assemblies and final inspection and, when practical, operation of manufactured equipment prior to shipment.

11

Since much of our polishing supplies segment’s know-how relates to the manufacture of its products, this segment’s facility is equipped to perform a significantly higher percentage of the fabrication steps required in the production of its products. However, injection molding for our insert carriers and the manufacture of raw cast iron plates are subcontracted out to various third parties. Our polishing supplies segment relies on key suppliers for certain materials, including two steel mills in Germany and Japan, an injection molder, a single-sourced pad supplier from Japan and an adhesive manufacturer. Prior to the fourth quarter of fiscal 2004, we subcontracted the laser-cutting of carriers to third parties. Since then we have purchased an advanced laser-cutting tool which has increased our ability to compete based upon price, delivery lead-times and quality. To minimize the risk of production and service interruptions and/or shortages of key parts, we maintain appropriate inventories of key raw materials and parts. If for any reason we were unable to obtain a sufficient quantity of parts in a timely and cost-effective manner to meet our production requirements, our results of operations would be materially and adversely affected.

RESEARCH, DEVELOPMENT AND ENGINEERING

The markets we serve are characterized by evolving industry standards and rapid technological change. To compete effectively in our markets, we must continually keep up with the pace of such change by improving our products and our process technologies and developing new technologies and products that compete effectively on the basis of price and performance and that adequately address current and future customer requirements. We continue to obtain as much customer cooperation and input as possible to increase the efficiency and effectiveness of our research and development efforts. While there can be no assurance that such relationships will continue or that others will be developed, such cooperative efforts are expected to remain a significant element in our future product and technology development projects.

In April 2007, we entered into a licensing and manufacturing agreement to develop and market an antireflective coating system for solar cells with PST Co., LTD. (“PST”). PST is a producer of vertical thermal processing systems for high-end semiconductor applications. This plasma-enhanced chemical vapor deposition (PECVD) system is used in high-volume, solar cell manufacturing and is an important step in the solar cell manufacturing process. The licensing agreement allows us to market PST’s existing PECVD system, and for PST to develop and manufacture a new PECVD model for us to market to high-volume solar cell manufacturers. In June 2008, we introduced the new PECVD system into the market.

In November 2008, the Company entered into a license agreement with PST to market PST’s existing and future proprietary PSG (phosphorus silicate glass) dry etch systems for the manufacture of photovoltaic cells. We introduced the PSG system into the market in July 2009.

On April 9, 2009, the Company entered into amendments with PST to both the PSG license and the PECVD license to expand the licenses to include one future model of the PSG dry etch systems and three future models of the PECVD system.

These 10-year licensing agreements will enable us to sell this product to our solar customer base through our extensive global sales and marketing network on an exclusive basis, with the exception of sales in Korea and to one existing customer of PST, for which PST retains exclusive rights. Additionally, we believe this product will enable us develop new customer relationships.

From time to time we add functionality to our products or develop new products during engineering and manufacturing to fulfill specifications in a customer’s order, in which case the cost of development, along with other costs of the order, are charged to cost of sales. We periodically receive small research grants for research and development of products in The Netherlands, which are netted against our research and development costs. Our approach to such expenditures has allowed us to produce a number of new products while spending amounts that we believe are generally modest in relation to most semiconductor equipment manufacturers. Our expenditures that have been accounted for as research and development were $0.5 million (1.0% of net revenue) for fiscal 2009, $1.1 million (1.4% of net revenue) for fiscal 2008 and $0.6 million (1.2% of net revenue) for fiscal 2007. These amounts exclude expenses supported by government grants.

12

PATENTS

The following table shows our material patents, the patents licensed by us, and the expiration date of each patent and license:

| Product | Country | Expiration Date or Pending Approval | ||

| IBAL Model S-300 | France, | March 21, 2021 | ||

| Germany, | Pending | |||

| Italy, | Pending | |||

| The Netherlands, | Pending | |||

| United Kingdom | Pending | |||

| Heating Element Wire Spacer | Europe | Pending | ||

| Photo CVD | United States | November 15, 2011 | ||

| Potential Damage-free Asher | United States | September 8, 2018 | ||

| IBAL Model S-300 | United States | July 7, 2019 | ||

| IBAL Model S-300 | United States | July 26, 2019 | ||

| IBAL Model E-300 | United States | July 13, 2021 | ||

| Fast, Safe, Pyrogenic External Torch Assembly (*) | United States | December 17, 2011 | ||

| Lapping Machine adjustable mechanism | United States | February 15, 2027 |

| (*) |

Patent is licensed from the patent holder or co-owner on a non-exclusive basis. |

To the best of our knowledge, there are no pending lawsuits against us regarding infringement of any existing patents or other intellectual property rights or any material unresolved claims made by third parties that we are infringing the intellectual property rights of such third parties.

SALES AND MARKETING

Because of the highly technical nature of our products, we market our products primarily by direct customer contact through our sales personnel and through a network of domestic and international independent sales representatives and distributors that specialize in semiconductor equipment and supplies. Our promotional activities include direct sales contacts, participation in trade shows, an Internet website, advertising in trade magazines and the distribution of product brochures.

Sales to distributors of both segments are generally on terms comparable to sales to end user customers, as our distributors generally quote their customers after first obtaining a quote from us and have an order from the end-user before placing an order with us. Our sales to distributors are not contingent on their future sales and do not include a general right of return. Historically, returns have been rare. Distributors of our solar and semiconductor equipment segment products do not stock a significant amount of our products, as the inventory they do hold is primarily limited to parts needed to provide timely repairs to the customer.

Payment terms of our parts, service and retrofit sales, which usually comprise approximately 50-60% of consolidated net revenue, are generally net 30 days, F.O.B. shipping point or equivalent terms. The payment terms of equipment or systems sales vary depending on the size of the order and the size, reputation and creditworthiness of the customer. As a result, the financial terms of equipment sales can range from 80% due 30 days after shipment and 20% due 30 days after acceptance, to requiring a 30% customer deposit 30 days after order placement, 60% due 30 days after shipment and 10% net due 30 days after acceptance. Letters of credit are required of certain customers depending on the size of the order, creditworthiness of the customer and the customers’ country of domicile.

13

During fiscal 2009, 82% of our net revenue came from customers outside of North America. This group represented 84% of revenues in fiscal 2008. In fiscal 2009, net revenue was distributed among customers in different geographic regions as follows: North America 18% (all of which is in the United States), Asia 68% (including 39% to China and 22% to Taiwan) and Europe 14%. During fiscal 2009, 2008 and 2007, one customer accounted for approximately 16%, 20%, and 13% of our net revenue, respectively. E-Ton Solar Tech accounted for 16%, 4% and 13% of our net revenue in fiscal 2009, 2008 and 2007, respectively. At the end of fiscal 2009 and 2008, 31% and 40% of our total backlog consisted of orders and deferred revenue from E-Ton Solar Tech, respectively. Our business is not seasonal in nature, but is cyclical based on the capital equipment investment patterns of solar cell and semiconductor manufacturers. These expenditure patterns are based on many factors, including anticipated demand for integrated circuits, the development of new technologies and global and regional economic conditions.

COMPETITION

We compete in several distinct markets including semiconductor devices, semiconductor wafer, solar cell, MEMS and the market for general industrial lapping and polishing machines and supplies. Each of these markets is highly competitive. Our ability to compete depends on our ability to continually improve our products, processes and services, as well as our ability to develop new products that meet constantly evolving customer requirements. Significant competitive factors for succeeding in the semiconductor manufacturing equipment market include the equipment’s technical capability, productivity and cost-effectiveness, overall reliability, ease of use and maintenance, contamination and defect control and the level of technical service and support provided by the vendor. The importance of each of these factors varies depending on the specific customer’s needs and criteria, including considerations such as the customer’s process application, product requirements, timing of the purchase and particular circumstances of the purchasing decision.

The Solar Cell Semiconductor Devices, Semiconductor Wafer, and MEMS Markets. Our diffusion furnaces and automation processing equipment primarily compete with those produced by other domestic and foreign original equipment manufacturers, some of which are well-established firms that are much larger and have substantially greater financial resources than us. Some of our competitors have a diversified product line, making it difficult to quantify their sales of products that compete directly with our products. Competitors of our horizontal diffusion furnaces include Centrotherm GmbH, Koyo Systems Co. Ltd., MRL Industries, Inc., a subsidiary of Sandvik AB, CVD Equipment, Inc., Semco Engineering S.A., Expertech, Inc. and Tystar Corporation. Competitors of our lapping and polishing machines and supplies include Lapmaster International, LLC, Hamai Co., Ltd., Speedfam Co., Ltd., Onse, Inc. and Eminess Technologies, Inc. Such competition could intensify in the future if the industry trend to produce smaller chips on larger wafers accelerates, or the newer technology represented by vertical furnaces results in a material shift in the purchasing habits of our targeted customers. Our furnaces and lapping and polishing machines also face, to a limited, but increasing extent, competition from used equipment on the low-end of the price spectrum.

General Industrial Lapping and Polishing Machines and Supplies Market. We experience price competition for wafer carriers produced by foreign manufacturers for which there is very little publicly available information. As a result, we are intensifying our efforts to reduce the cost of our carriers and will continue to compete with other manufacturers of carriers by continuing to update our product line to keep pace with the rapid changes in our customers’ requirements and by providing a high level of quality and customer service. During September 2004, we completed the installation and began producing steel carriers, including insert carriers, on an advanced laser-cutting tool, which has reduced the costs and lead times of these products and increased our control over quality. Competitors of our lapping and polishing machines and carriers, other than insert carriers, include Speedfam-PW, a division of Novellus, among others. We have been able to capture a small share of the semiconductor polishing template market, which we believe to be dominated by Rodel, a division of Rohm and Haas. Our strategy to enhance our sales of wafer carriers includes developing additional niche markets for templates and providing a high level of customer support and products at a lower cost than our competitors.

EMPLOYEES

As of September 30, 2009, we employed approximately 190 people. Of these employees, approximately 10 were based at our corporate offices in Tempe, Arizona, 30 at our manufacturing plant in Carlisle, Pennsylvania, 10 at our manufacturing plant in Billerica, Massachusetts, 85 at our facilities in The Netherlands, 35 at our facilities in France and 20 in our contract semiconductor manufacturing support services business located in Austin, Texas. Of the approximately 30 people employed at our Carlisle, Pennsylvania facility, about 19 were represented by the United Auto Workers Union - Local 1443. We have never experienced a work stoppage or strike. We consider our employee relations to be good.

14

AVAILABLE INFORMATION

Our annual, quarterly and current reports, proxy statements and other information, including the amendments to those reports, are available, without charge, on our website, www.amtechsystems.com, as soon as reasonably practicable after they are filed electronically with the Securities and Exchange Commission (“SEC”). In addition, our SEC filings are available over the internet at the SEC’s website at http://www.sec.gov.

You may also read and copy any document that we file at the SEC’s public reference room at:

Public Reference Room

100 F Street,

N.E.

Washington, D.C. 20549

1-800-SEC-0330

Please call the SEC at 1-800-SEC-0330 for more information on the public reference room and their copy charges. Copies of our key governance documents, code of ethics, and charters of our audit, compensation and corporate governance committees are also available on our website.

Information contained on our website is not part of this Annual Report and is not incorporated in this Annual Report by reference.

ITEM 1A. RISK FACTORS

Because of the following factors, as well as other variables affecting our operating results and financial condition, past performance may not be a reliable indicator of future performance, and historical trends should not be used to anticipate results or trends in future periods.

Risks Related to our Business and Industry.

Recent deterioration in the global economy and credit markets may materially and adversely affect our future results of operations.

Our operations may be adversely affected by the recent deterioration in the global economy causing our customers to delay or cease spending on our products. The recent tightening of the credit markets may negatively impact our operations by affecting the liquidity and/or solvency of our customers and key suppliers and the ability of our customers to obtain credit to finance purchases of our products. If the global economy and credit markets continue to deteriorate, our financial condition and results of operations will likely be adversely impacted. We have no way of determining how long the global economic crisis, including the tightening of credit markets, will last.

If demand declines for horizontal diffusion furnaces and related equipment, or for solar industry products, our financial position and results of operations could be materially and adversely affected.

The revenue of our solar and semiconductor equipment segment, which accounted for approximately 89% of our consolidated net revenue as of September 30, 2009, is comprised primarily of sales of horizontal diffusion furnaces and our automation products. Our automation products are useable only with horizontal diffusion furnaces. There is a trend in the semiconductor industry, related to the trend to produce smaller chips on larger wafers, towards the use in semiconductor manufacturing facilities of newer technology, such as vertical diffusion furnaces. Vertical diffusion furnaces are more efficient than the horizontal diffusion furnaces in certain manufacturing processes for smaller chips on larger wafers. As early as 1994, we had expected that demand for our horizontal diffusion furnaces would decline as a result of this trend. We believe this trend has not yet adversely affected us to the extent originally expected. However, to the extent that the trend to use vertical diffusion furnaces over horizontal diffusion furnaces continues, our revenue may decline and our corresponding ability to generate income may be adversely affected. A significant part of our growth strategy involves expanding our sales to the solar industry. The solar industry is subject to risks relating to industry shortages of polysilicon, (which we discuss further below), the continuation of government incentives, the availability of specialized capital equipment, global energy prices and rapidly changing technologies offering alternative energy sources. If the demand for solar industry products declines, the demand by the solar industry for our products would also decline and our financial position and results of operations would be harmed.

15

We may not be able to increase or sustain our recent growth rate, and we may not be able to manage our future growth effectively.

We may be unable to continue to expand our business or manage future growth. Our recent expansion has placed, and our planned expansion and any other future expansion will continue to place, a significant strain on our management, personnel, systems and resources. In the past two years, we purchased additional equipment and real estate to significantly expand our manufacturing capacity and expect to hire additional employees to support an increase in manufacturing, research and development and sales and marketing efforts. To successfully manage our growth, we believe we must effectively:

-

hire, train, integrate and manage additional process engineers, field service engineers, sales and marketing personnel, and financial and information technology personnel;

-

retain key management and augment our management team, particularly if we lose key members;

-

continue to enhance our customer resource management and manufacturing management systems;

-

implement and improve additional and existing administrative, financial and operations systems, procedures and controls;

-

expand and upgrade our technological capabilities; and

-

manage multiple relationships with our customers, suppliers and other third parties.

We may encounter difficulties in effectively managing the budgeting, forecasting and other process control issues presented by rapid growth. If we are unable to manage our growth effectively, we may not be able to take advantage of market opportunities, develop new solar cells and other products, satisfy customer requirements, execute our business plan or respond to competitive pressures.

The ongoing volatility of the solar and semiconductor equipment industry may negatively impact our business and results of operations and our corresponding ability to efficiently budget our expenses.

The solar and semiconductor equipment industries are highly cyclical. As such, demand for and the profitability of our products can change significantly from period to period as a result of numerous factors, including, but not limited to, changes in:

-

global and regional economic conditions;

-

changes in capacity utilization and production volume of manufacturers of semiconductors, silicon wafers, solar cells and MEMS;

-

the shift of semiconductor production to Asia, where there often is increased price competition; and

-

the profitability and capital resources of those manufacturers.

For these and other reasons, our results of operations for past periods may not necessarily be indicative of future operating results.

16

Since our business has historically been subject to cyclical industry conditions, we have experienced significant fluctuations in our quarterly new orders and net revenue, both within and across years. Demand for solar semiconductor and silicon wafer manufacturing equipment and related consumable products has also been volatile as a result of sudden changes in solar and semiconductor supply and demand and other factors in both semiconductor devices and wafer fabrication processes. Our orders tend to be more volatile than our revenue, as any change in demand is reflected immediately in orders booked, which are net of cancellations, while revenue tends to be recognized over multiple quarters as a result of procurement and production lead times and the deferral of certain revenue under our revenue recognition policies. Customer delivery schedules on large system orders can also add to this volatility since we generally recognize revenue for new product sales on the date of customer acceptance or the date the contractual customer acceptance provisions lapse. As a result, the fiscal period in which we are able to recognize new products revenue is typically subject to the length of time that our customers require to evaluate the performance of our equipment after shipment and installation, which could cause our quarterly operating results to fluctuate.

The purchasing decisions of our customers are highly dependent on the economies of both their domestic markets and the worldwide semiconductor industry. The timing, length and severity of the up-and-down cycles in the semiconductor equipment industry are difficult to predict. The cyclical nature of our marketplace affects our ability to accurately budget our expense levels, which are based in part on our projections of future revenue.

When cyclical fluctuations result in lower than expected revenue levels, operating results may be adversely affected and cost reduction measures may be necessary in order for us to remain competitive and financially sound. During a down cycle, we must be able to make timely adjustments to our cost and expense structure to correspond to the prevailing market conditions. In addition, during periods of rapid growth, we must be able to increase manufacturing capacity and personnel to meet customer demand, which may require additional liquidity. We can provide no assurance that these objectives can be met in a timely manner in response to changes within the industry cycles. Our failure to respond to these cyclical changes could have a material adverse affect on our business.

During the most recent down cycle, beginning in the first half of 2001, the semiconductor industry experienced excess production capacity that caused semiconductor manufacturers to decrease capital spending. We do not have long-term volume production contracts with our customers and we do not control the timing or volume of orders placed by our customers. Whether and to what extent our customers place orders for any specific products and the mix and quantities of products included in those orders are factors beyond our control. Insufficient orders would result in under-utilization of our manufacturing facilities and infrastructure and will negatively affect our financial position and results of operations.

The Company has made substantial investments in its organization to develop new products for the solar industry. Sales of our products to the solar industry are subject to substantial risks.

The solar energy sector is partially dependent upon governmental subsidies that are not guaranteed to continue. A decline in these subsidies would reduce our ability to grow our business in this market.

The semiconductor equipment industry is competitive and we are relatively small in size and have fewer resources in comparison with our competitors.

Our industry includes large manufacturers with substantial resources to support customers worldwide. Our future performance depends, in part, upon our ability to continue to compete successfully worldwide. Some of our competitors are diversified companies having substantially greater financial resources and more extensive research, engineering, manufacturing, marketing and customer service and support capabilities than we can provide. We face competition from companies whose strategy is to provide a broad array of products, some of which compete with the products and services that we offer. These competitors may bundle their products in a manner that may discourage customers from purchasing our products. In addition, we face competition from smaller emerging semiconductor equipment companies whose strategy is to provide a portion of the products and services that we offer at often a lower price than ours, using innovative technology to sell products into specialized markets. Loss of competitive position could impair our prices, customer orders, revenue, gross margin and market share, any of which would negatively affect our financial position and results of operations. Our failure to compete successfully with these other companies would seriously harm our business. There is a risk that larger, better-financed competitors will develop and market more advanced products than those that we currently offer, or that competitors with greater financial resources may decrease prices thereby putting us under financial pressure. The occurrence of any of these events could have a negative impact on our revenue.

17

We are dependent on key personnel for our business and product development and sales, and any loss of our key personnel to competitors or other industries could dramatically impact our ability to continue operations.

Historically, our product development has been accomplished through cooperative efforts with key customers. Our relationship with some customers is substantially dependent on personal relations established by our President and Chief Executive Officer. Furthermore, our relationship with a major European customer that has been instrumental in the development of our small batch vertical furnace is substantially dependent upon our European General Manager. We are also dependent upon our Technical Director of R2D for the development of our automation technology. While there can be no assurance that such relationships will continue, such cooperation is expected to continue to be a significant element in our future development efforts thereby continuing our reliance on certain of our key personnel.

We are the beneficiary of life insurance policies on the life of our President and Chief Executive Officer, Mr. J. S. Whang, in the amount of $2.0 million, but there is no assurance that such amount will be sufficient to cover the cost of finding and hiring a suitable replacement for Mr. Whang. It may not be feasible for any successor to maintain the same business relationships that Mr. Whang has established. If we were to lose the services of Mr. Whang for any reason, it could have a material adverse affect on our business.

We also depend on the management efforts of our officers and other key personnel and on our ability to attract and retain key personnel. During times of strong economic growth, competition is intense for highly skilled employees. There can be no assurance that we will be successful in attracting and retaining such personnel or that we can avoid increased costs in order to do so. There can be no assurance that employees will not leave Amtech or compete against us. Our failure to attract additional qualified employees, or to retain the services of key personnel, could negatively impact our financial position and results of operations.

We may not be able to keep pace with the rapid change in the technology we use in our products.

Success in the solar and semiconductor equipment industries depends, in part, on continual improvement of existing technologies and rapid innovation of new solutions. For example, the semiconductor industry continues to shrink the size of semiconductor devices. These and other evolving customer needs require us to respond with continued development programs.

Technical innovations are inherently complex and require long development cycles and appropriate professional staffing. Our future business success depends on our ability to develop and introduce new products, or new uses for existing products, that successfully address changing customer needs, win market acceptance of these new products or uses and manufacture any new products in a timely and cost-effective manner. To realize future growth through technical innovations in the solar and semiconductor industries, we must either acquire the technology through merger and acquisition activity or through the licensing of products from our technology partners. Our failure to develop and introduce new products, technologies or uses for existing products in a timely manner and continually find ways of reducing the cost to produce them in response to changing market conditions or customer requirements, could have a material adverse affect on our business.

Acquisitions can result in an increase in our operating costs, divert management’s attention away from other operational matters and expose us to other risks associated with acquisitions.

We continually evaluate potential acquisitions and consider acquisitions an important part of our future growth strategy. In the past, we have made acquisitions of, or significant investments in, other businesses with synergistic products, services and technologies and plan to continue to do so in the future. Acquisitions, including our recent acquisition of R2D, involve numerous risks, including, but not limited to:

-

difficulties and increased costs in connection with integration of geographically diverse personnel, operations, technologies and products of acquired companies;

18

-

diversion of management’s attention from other operational matters;

-

the potential loss of key employees of acquired companies;

-

lack of synergy, or inability to realize expected synergies, resulting from the acquisition;

-

the risk that the issuance of our common stock, if any, in an acquisition or merger could be dilutive to our shareholders, if anticipated synergies are not realized; and

-

acquired assets becoming impaired as a result of technological advancements or worse-than-expected performance of the acquired company.

Our financial position and results of operations may be materially harmed if we are unable to recoup our investment in research and development.

The rapid change in technology in our industry requires that we continue to make investments in research and development in order to enhance the performance and functionality of our products, to keep pace with competitive products and to satisfy customer demands for improved performance, features and functionality. There can be no assurance that revenue from future products or enhancements will be sufficient to recover the development costs associated with such products or enhancements, or that we will be able to secure the financial resources necessary to fund future development. Research and development costs are typically incurred before we confirm the technical feasibility and commercial viability of a product, and not all development activities result in commercially viable products. In addition, we cannot ensure that products or enhancements will receive market acceptance, or that we will be able to sell these products at prices that are favorable to us. If we are unable to sell our products at favorable prices, or if our products are not accepted by the markets in which we operate, it could have a material adverse affect on our business.

If third parties violate our proprietary rights, in which we have made significant investments, such events could result in a loss of value of some of our intellectual property or costly litigation.

Our success is dependent in part on our technology and other proprietary rights. We own various United States and international patents and have additional pending patent applications relating to some of our products and technologies. The process of seeking patent protection is lengthy and expensive, and we cannot be certain that pending or future applications will actually result in issued patents, or that issued patents will be of sufficient scope or strength to provide meaningful protection or commercial advantage to us. Other companies and individuals, including our larger competitors, may develop technologies that are similar or superior to our technology or design around the patents we own or license. We also maintain trademarks on certain of our products and claim copyright protection for certain proprietary software and documentation. However, we can give no assurance that our trademarks and copyrights will be upheld or successfully deter infringement by third parties. Recently, the patent covering technology that we license and use in our manufacture of insert carriers has expired, which may have the effect of diminishing or eliminating any competitive advantage we may have with respect to this manufacturing process.

While patent, copyright and trademark protection for our intellectual property is important, we believe our future success in highly dynamic markets is most dependent upon the technical competence and creative skills of our personnel. We attempt to protect our trade secrets and other proprietary information through confidentiality agreements with our customers, suppliers, employees and consultants and through other security measures. We also maintain exclusive and non-exclusive licenses with third parties for the technology used in certain products. However, these employees, consultants and third parties may breach these agreements, and we may not have adequate remedies for wrongdoing. In addition, the laws of certain territories in which we develop, manufacture or sell our products may not protect our intellectual property rights to the same extent as do the laws of the United States.

We may face intellectual property infringement claims that could be time-consuming and costly to defend and could result in our loss of significant rights and the assessment of treble damages.

19

From time to time, we have received communications from other parties asserting the existence of patent rights or other intellectual property rights that they believe cover certain of our products, processes, technologies or information. In such cases, we evaluate our position and consider the available alternatives, which may include seeking licenses to use the technology in question on commercially reasonable terms or defending our position. We cannot ensure that licenses can be obtained, or if obtained will be on acceptable terms, or that litigation or other administrative proceedings will not occur.

Some of these claims may lead to litigation. We cannot assure you that we will prevail in these actions, or that other actions alleging misappropriation or misuse by us of third-party trade secrets, infringement by us of third-party patents and trademarks or the validity of our patents, will not be asserted or prosecuted against us. Intellectual property litigation, regardless of outcome, is expensive and time-consuming, could divert management’s attention from our business and have a material negative effect on our business, operating results or financial condition. If there is a successful claim of infringement against us, we may be required to pay substantial damages (including treble damages if we were to be found to have willfully infringed a third party’s patent) to the party claiming infringement, develop non-infringing technology, stop selling or using technology that contains the allegedly infringing intellectual property or enter into royalty or license agreements that may not be available on acceptable or commercially practical terms, if at all. Our failure to develop non-infringing technologies or license the proprietary rights on a timely basis could harm our business. Parties making infringement claims on future issued patents may be able to obtain an injunction that would prevent us from selling or using our technology that contains the allegedly infringing intellectual property, which could harm our business.

Our reliance on sales to a few major customers and granting credit to those customers places us at financial risk.

We currently sell to a relatively small number of customers, and we expect our operating results will likely continue to depend on sales to a relatively small number of customers for the foreseeable future, as well as the ability of these customers to sell products that require our products in their manufacture. During fiscal 2009 16% of net revenue was generated by one customer, E-Ton Solar Tech. E-Ton Solar Tech was also our largest customer in fiscal 2007. At the end of fiscal 2009 and 2008, 31% and 40% of our backlog consists of open sales orders and deferred revenue from E-Ton Solar Tech, respectively. Many of our customer relationships have been developed over a short period of time and certain customers are in their preliminary stages of development. The loss of sales to any of these customers would have a significant negative impact on our business. Our agreements with these customers may be cancelled if we fail to meet certain product specifications, materially breach the agreement or in the event of bankruptcy, and our customers may seek to renegotiate the terms of current agreements or renewals. We cannot be certain that these customers will generate significant revenue for us in the future nor that these customer relationships will continue to develop. If our relationships with our other customers do not continue to develop, we may not be able to expand our customer base or maintain or increase our revenue.

As of September 30, 2009, accounts receivable from three customers each exceeded 10% of accounts receivable; these three customers accounted for 19%, 11% and 10% of total accounts receivable, respectively. A concentration of our receivables from one or a small number of customers places us at risk. If any one or more of our major customers does not pay us it could adversely affect our financial position and results of operations. We attempt to manage this credit risk by performing credit checks, by requiring significant partial payments prior to shipment where appropriate and by actively monitoring collections. We also require letters of credit of certain customers depending on the size of the order, type of customer or its creditworthiness and its country of domicile.

If any of our customers cancels or fails to accept a large system order, our financial position and results of operations could be materially and adversely affected.

Our backlog includes orders for large systems, such as our diffusion furnaces, with system prices of up to and in excess of $1.0 million depending on the system configuration, options included and any special requirements of the customer. Because our orders are typically subject to cancellation or delay by the customer, our backlog at any particular point in time is not necessarily representative of actual sales for succeeding periods, nor is backlog any assurance that we will realize revenue or profit from completing these orders. Our financial position and results of operations could be materially and adversely affected should any large systems order be cancelled prior to shipment, or not be accepted by the customer. We have experienced significant cancellations in the past, including $1.2 million in fiscal 1999, $3.5 million in 2001, and $1.2 million in 2002. We have not experienced any significant cancellations since 2002. Likewise, a significant change in the liquidity or financial position of any of our customers that purchase large systems could have a material impact on the collectability of our accounts receivable and our future operating results. Our backlog does not provide any assurance that we will realize revenue or profit from those orders or indicate in which period net revenue will be recognized, if ever.

20

Our business might be adversely affected by a decline in our sales to foreign customers, significant exchange rate fluctuations and foreign laws.

During fiscal 2008, 84% of our net revenue came from customers outside of North America. During fiscal 2009, 82% of our net revenue came from customers outside of North America as follows:

-

Asia – 68% (includes 39% to China and 22% to Taiwan); and

-

Europe – 14%.

Because of our significant dependence on revenue from international customers, our operating results could be negatively affected by a decline in the economies of any of the countries or regions in which we do business. Each region in the global semiconductor equipment market exhibits unique characteristics that can cause capital equipment investment patterns to vary significantly from period to period. Periodic local or international economic downturns, trade balance issues, political instability and fluctuations in interest and currency exchange rates could negatively affect our business and results of operations. In addition, we face competition from a number of suppliers based in Asia that have certain advantages over suppliers from outside of Asia. These advantages include lower operating and regulatory costs, proximity to customers and favorable tariffs.